|

We are delighted to announce that our first project, the X-Plorer 1, has been honoured in the global design competition, Project of the Year 2017, organised by Dassault Systèmes!

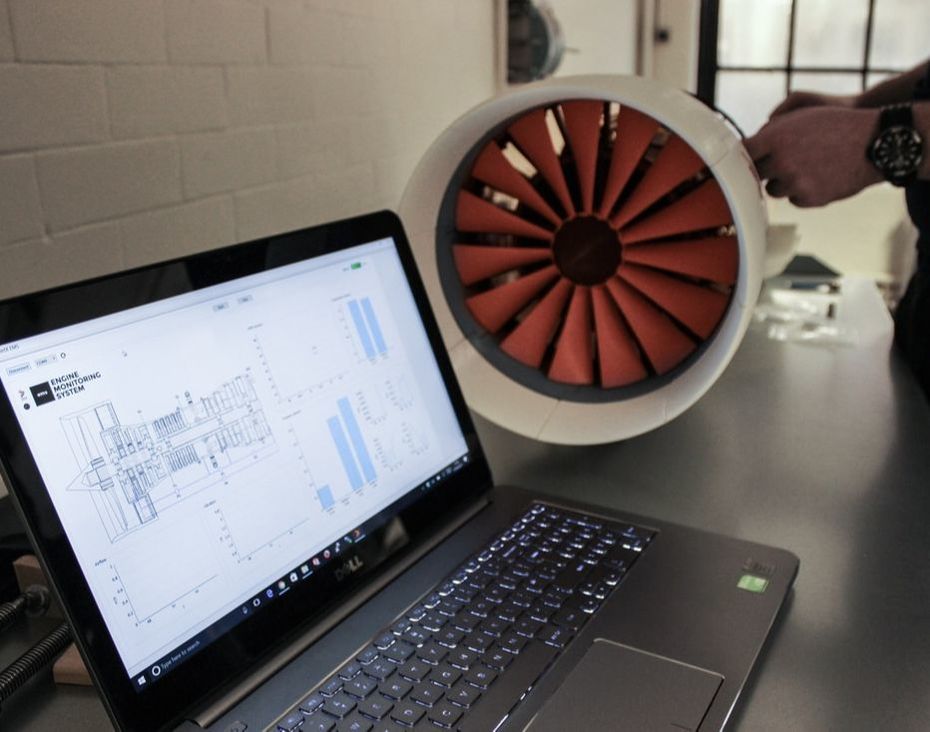

The competition which ran from April through June received 214 entries across a wide range of areas including aerospace, automotive, product design, biomedical and materials engineering from all over the world. Dassault Systèmes is the French multinational software company behind major engineering tools such as Solidworks, CATIA and SIMULIA. The X-Plorer 1 has been designed entirely using Solidworks, which has also allowed us to perform initial simulations to examine structural integrity and performance. Dassault Systèmes was ranked second in the Corporate Knights Top 100 Most Sustainable Corporations in the World in 2016 and was the highest ranked technology company on the list. Each of the three brands' prizes were awarded by a jury consisting of two professionals for each respective software which judged the entries "on the basis of several criteria including innovation, originality, technicality, optimal use of the Solidworks solution, work carried out and any other similar criteria." The X-Plorer 1 was one of two UK entries that won an award, along with Gaetano Arena from the University of Bristol for his work on morphing structures for flow regulation, modelled using SIMULIA. Apart from winning the Solidworks jury prize, the X-Plorer 1 also came 9th in the public vote and we would like to thank each and every person that voted for us and picked our project among the hundreds submitted! Both awards, along with the news that the XP1 has also been shortlisted for the upcoming 3D Hubs Student Grant final are incredible rewards in recognition of the hard work and dedication that the team has shown in the last two and a half years! We want to take this forward and not only engage more students next year, but also keep on encouraging younger people to become the pioneers of tomorrow! The X-Plorer 1 has successfully completed the first phase of testing which included a series of static runs! This was the first time the engine was actuated by air alone with the structural integrity of the 3D-printed assembly also put to the test. The on-board electronics were also tested for performance in the range exhibited by the XP1.

Reaching this milestone means that we not only have a working model to the capacity that we expected but also that it has cleared checks for wind tunnel testing which will be scheduled for autumn 2017. JetX president Chris Triantafyllou said: Today marks a major milestone for this project which has been in the making for the past two and a half years! We have now acquired data or identified areas to be improved that would not otherwise be possible before or without testing. The fact that the engine remains in full working condition means that we plan to perform wind tunnel testing as well as operate it for longer and at higher speeds. We would also like to thank our trusted partner Cole-Parmer for their continuing support and extremely fast response for the evolving needs for instrumentation during testing! As the development of the X-Plorer 2 will be at full speed during the upcoming academic year, we would also like to thank each and every partner of ours during the design and manufacture of the X-Plorer 1! Check them out here.

|

JetX Engineering NewsFor all latest updates on the club, the team & the project. Archives

November 2020

Categories

All

|

The Project |

The People |

|

© COPYRIGHT 2014-2021. JetX Engineering ®

RSS Feed

RSS Feed