|

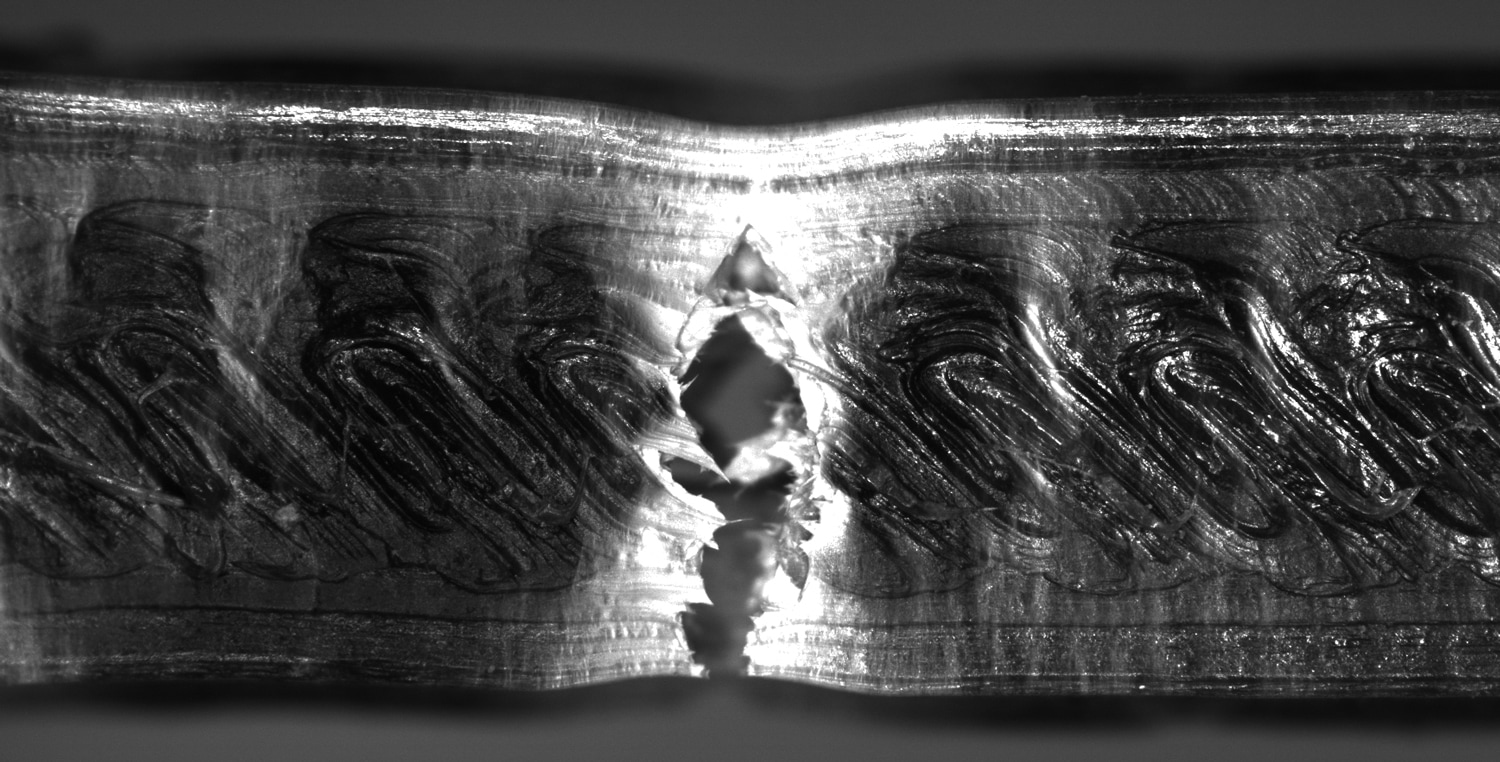

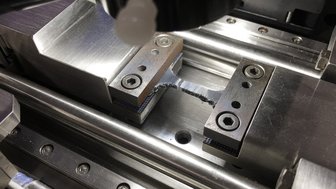

Last week saw testing across three areas taking place to either test components before these are fitted onto the X-Plorer 1 or to enhance our understanding of the mechanical behaviour of 3D printed parts. The week kicked off with electronics checks to test the performance of sensors in environments more realistic to the anticipated in-service ones, check the wireless communication links and readiness of the Graphical User Interface (GUI). 5 sensors have already passed the checks, 1 is pending and issues identified with 4 of them are being addressed this week. The GUI was also found to respond and function well, with only a few bugs left to be sorted by our software engineers. Finally, we conducted a series of preliminary mechanical tests on 3D printed specimen, manufactured in different orientations. The purpose of these experiments was to quantify the relation and degree of dependency of the 3D printing structure on the mechanical (tensile) capacity of the part. Apart from enabling us to observe the difference in failure modes, the tests have given us data that will be used to optimise and build more complex and accurate FEA models that are based on composite structures. The long-term objective is computationally model 3D printed parts more accurately, which is particularly challenging due to a number of factors. Testing will continue this week, as assembly progresses. A failure of an LP shaft segment led to intensive work by several of our design engineers who have come up with an improved design. Even though re-printing the parts meant that just over 115 hours were added to the printing schedule, the new design is thought to offer multiple benefits and its immediate implementation will be completed by next week. This months a series of tasks enter the last stages, as we've reach the last 16 of the batch of 260 initially scheduled prints!

Some adjustments are being made to ease final assembly and we will soon be able to share images from the assembly progress of the actual X-Plorer 1. In the meantime, we've put together a stunning animation of the virtual assembly, giving you a glimpse of the number and variety of components on the engine. Vibrant colours and dramatic music aside, virtual assemblies are extensively used as part of the design process and are essential in avoiding interferences and other issues that typically arise when components from different teams come together. |

JetX Engineering NewsFor all latest updates on the club, the team & the project. Archives

November 2020

Categories

All

|

The Project |

The People |

|

© COPYRIGHT 2014-2021. JetX Engineering ®

RSS Feed

RSS Feed