|

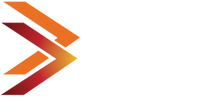

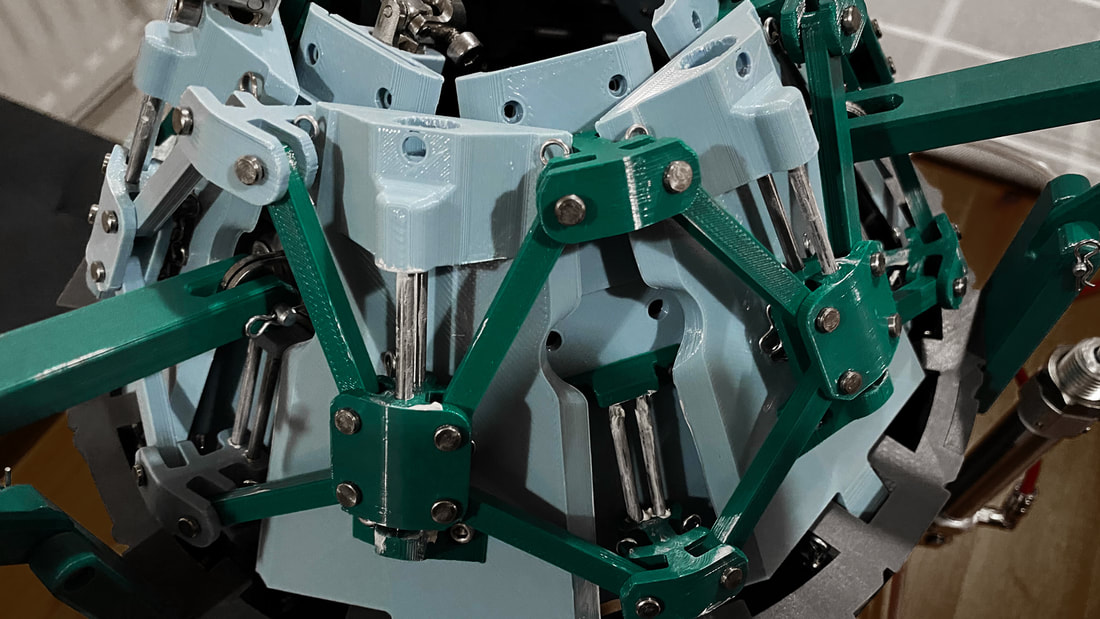

It goes without saying that 2020 hasn't turned out as planned for pretty much everyone, ourselves included. With the pandemic still affecting a big part of our everyday lives, consecutive project delays and a nearly-spent budget, it has been difficult to keep the momentum going over the last few months. However, here's how we managed to get a great deal of work done to piece together our most complicated project. Kronos vs X-Plorer 2 Since the beginning of the previous academic year, we were conscious of Kronos falling behind schedule and decided to focus our efforts on it, meaning that little manpower was left for X-Plorer 2. Given that Kronos has taken the centre stage since 2018-2019, this wasn't a big disruption to our work schedule, but it did mean that X-Plorer 2 was eventually suspended and unfortunately we have no plans to continue it anytime soon. We tried our best to remain equally committed to both programmes since 2017 for different reasons; X-Plorer 2 being a natural evolution of the 1 and EC predecessors would allow us to fine tune things that have been flagged up during the assembly and use of both. It was about making better use of the information gathered in the process, whereas Kronos came with a whole new set of features and subsystems that we were very excited to bring to life. After all, Kronos was the much bigger challenge for us and we couldn't not continue the tremendous amount of work that has gone into it over the last three years. Where are we now? By the start of February, aerofoils work was almost complete but we were faced with difficulties around the exhaust and the vectoring assembly. For the Kronos core, the integration work began in March, bringing together the work of different teams in our largest assembly structure to date, which currently includes 114 unique subassembly configurations and a total number of 3081 components! During lockdown we managed to complete a large percentage of essential test prints, but were faced with a hardware failure of our resin printer which pushed us back for another couple of months. As of November, we've clocked in over 300 hours for FDM test prints and 200 hours for DLP prints, which include over 100 fir tree tests for different stages and a near full-complexity prototype of the variable exhaust. We have also completed crucial electronics testing, from validating new airspeed sensors, electropneumatics control, visual feedback/LEDs and heat control. Coming up We are currently testing some final mechanical aspects of the exhaust and once this has been approved the final printing will begin! This might happen before the end of the year, but it is now evident that project completion is scheduled for mid 2021 assuming no major obstructions get in the way again.

Over the past three years, we have devoted a huge amount of time and resources towards Kronos, which further intensified in the last year. There were a lot of things that didn't go exactly to plan but our goal is now within reach and we can't wait to put all the pieces together! We can confirm that Kronos is our final project but we would like to thank all of you that have supported us over the years to any capacity. We will have some exciting updates over the next few months, so keep an eye out for them! |

JetX Engineering NewsFor all latest updates on the club, the team & the project. Archives

November 2020

Categories

All

|

The Project |

The People |

|

© COPYRIGHT 2014-2021. JetX Engineering ®

RSS Feed

RSS Feed