Final full team meeting for the academic year takes place as momentum builds up for Kronos25/4/2019

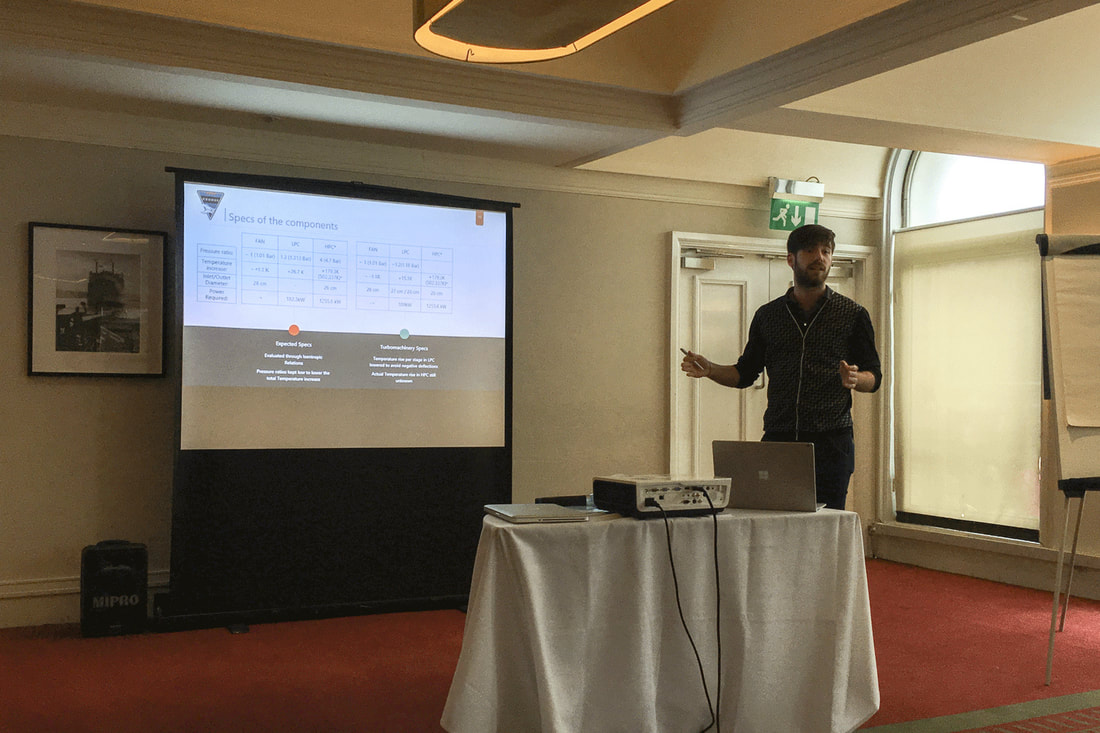

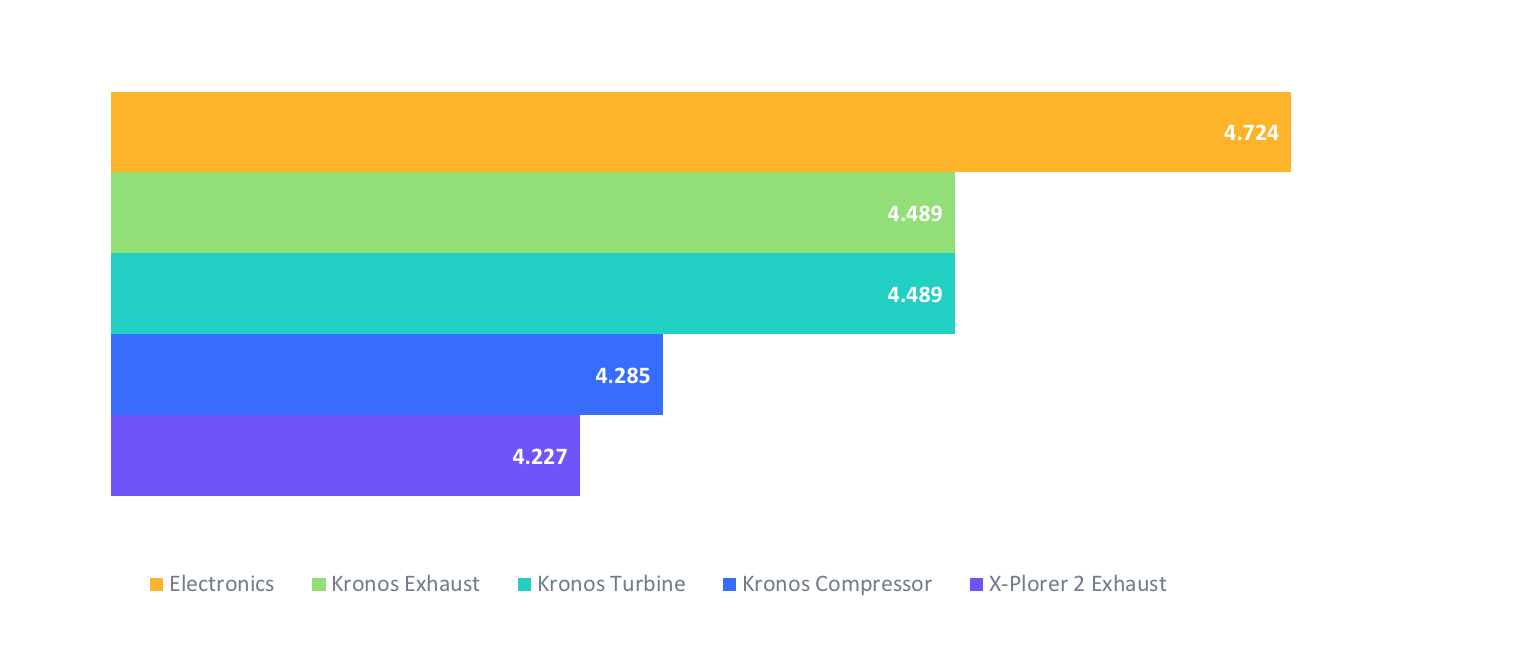

Last week, we all met for the final team presentation for this semester in a 5-hour session full of computational results, experimental findings, future plans and coffee! All teams were asked to deliver a technical presentation on all the work carried out during the academic year. Despite this being a seemingly quiet year, we had extensive discussions on the large amount of work carried out across all areas/teams. The absolute team progress has been very encouraging as far as the Kronos timeline is concerned and coincides with a strong development of computational skills which drives future design improvements. We also briefly discussed the progress of another project that has not be shared publicly so far, but it has certainly taken up several hundreds of hours for a sub-team of ours to deliver. Keep an eye our for our next news post to find out more about it! Finally, thanks to our sponsor MeetingPulse we were once again able to effortlessly collect peer assessment data during our event, where the rest of the team was asked to rate the presenters in terms of overall progress, technical content and presentations skills. Unfortunately, the Electronics team was not able to win for the second year in a row, but we'd like to congratulate the Exhaust team for scoring a total of 27.32 points out of 30 and for topping the board for each individual category too!

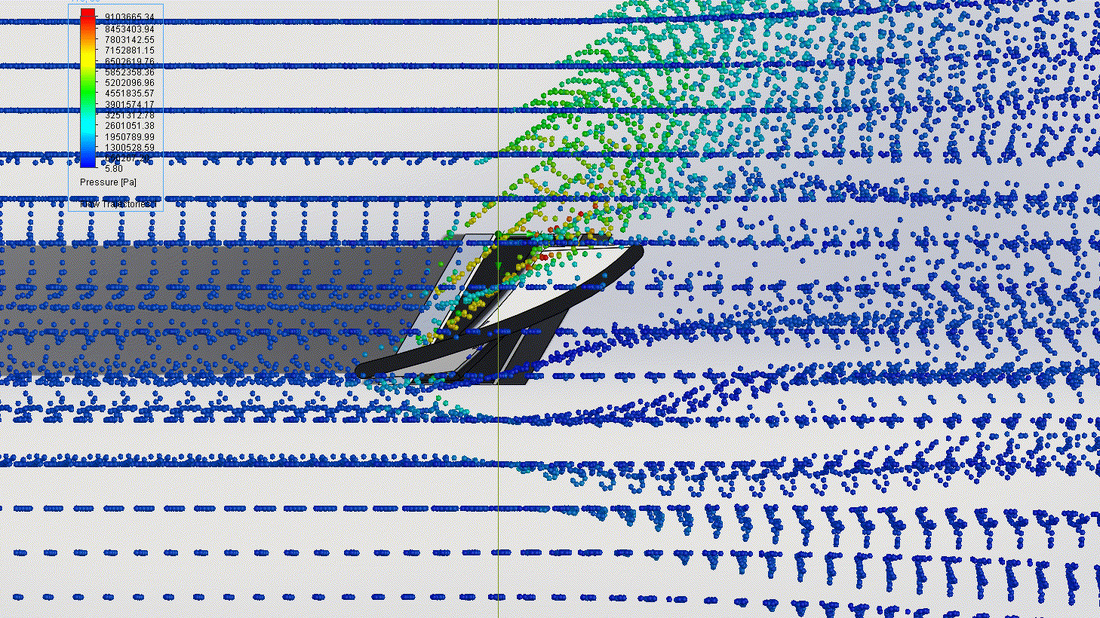

Kronos Power Transmission team leader Murray Mackenzie, presented the latest updates from his team. Our third and final full team meeting for this academic year took place on Monday, amid anticipation to view the latest updated on the work across all teams! The meeting held at Hilton Glasgow Grosvenor was, in fact, the longest we have ever had, stretching over 6 hours (but we did have a lunch break)! Highlights from the X-Plorer 2 team include major progress on one of the high priority items on our agenda- the finite element modelling of 3D printed parts. The Power Transmission team has been working on recreating the geometry of an actual 3D printed part from the tool paths with the ultimate goal being to calibrate a model using ANSYS so that the significant anisotropy is taken into account. One of the two members leading the FEA research, Paul Strang, said: I think that our work on gcode-based FEA modelling is one of the most exciting areas to be working on. We have made good progress this semester and I am glad to have had the chance to get involved. Of course, we haven't reached our goal yet and will hope that we'll have a breakthrough in the next few months, as our modelling in ANSYS gets more elaborate and some testing is completed. Exhaust also presented a newer, more elaborate design for the thrust reversers that will be introduced to the X-Plorer 2, with some additional work required to address scaling issues. Progress from Kronos has been impressive, with the programme running ahead of schedule despite the initially challenging theoretical design stage. The exhaust team stood out, showing major progress on the nozzle and afterburner design and managed to run initial CFD simulations in the limited amount of time for computational simulations this semester. Exhaust team leader, Cami Leslie said: Having worked on both the X-Plorer 1 and 2, Kronos is the programme was most excited to hear about and despite the heavy workload associated with starting the design from scratch, we were incredibly motivated to deliver some of the most challenging and impressive components. I am very proud of the work we presented today and we are looking forward to seeing it to completion next year! Kronos Compressor team member Cosimo Nastasia, gave a thorough presentation on the team's theoretical model. Electronics presented what is expended to be the most major improvement for the entire EMS, both for hardware and software. The team's careful planning and appreciation for the way the systems will integrate with the upcoming engines, enabled the rest of the team to appreciate the work which most others don't usually have to get involved with. The team is expected to deliver the new system by July, when it will be used for an X-Plorer 1 variant. One of the most engaging features of our final presentations is the ability for members to vote for other teams' presentations in real time and assess them in three areas: presentation skills, technical content and overall progress. This year, this was enabled using MeetingPulse! Through their kind sponsorship, we ran live polling easier than ever before and gathered all data to present at the end of the meeting. 88% of attendees said that the use of MeetingPulse made the meeting and presentations more engaging and 7 out 10 stated that it made the process more competitive! Overall Top 5This meeting has been sponsored by

JetX members from 10 teams and 2 programmes came together last week to assess progress during the first semester, individual performance and each team's plans and strategies for the current semester. The meeting, which was held at Hilton Glasgow Grosvenor, took place at the end of the most exhaustive review process so far. Feedback was collected from all levels within the organisation, from the junior team members to the board members and each team and team leader was assessed for the team function, performance, skills & personal experience. The 39-page internal report gives a good idea to all teams about any particular areas where the might have missed the target and how they compare against all other teams. Chris said: The review not only gives us an opportunity to evaluate all teams, given that the number has doubled in the last year, but also enables us to provide useful feedback or information at a time when the teams can learn from it and use it constructively for the current semester. Overall, we have been very satisfied with the progress so far and the performance of most teams. Feedback also shows that our implementation of Freedcamp earlier this year has improved cross-team communication, which has been problematic in the past. Most X-Plorer 2 teams are almost ready to deliver key performance and assembly improvements to the engine programme, whilst Kronos has made a steady start in laying the design foundations. Electronics has already delivered some interim solutions to problems of the EMS and is working towards the new system. Congratulations to the X-Plorer 2 Turbine team and Hannah Garcia Doherty for being the top scorers in the team performance and team leadership categories respectively for this semester! The full team will come together again in March for a more in-depth technical review. We would also like to thank the staff at Hilton Glasgow Grosvenor for their help and hospitality! In the meantime, a small number of vacancies has become available for both programmes and our applications are now open! Applications at this time of the year are reviewed on a rolling basis and may close as soon as vacancies are filled. You can find out more by visiting this page. Related Sponsors

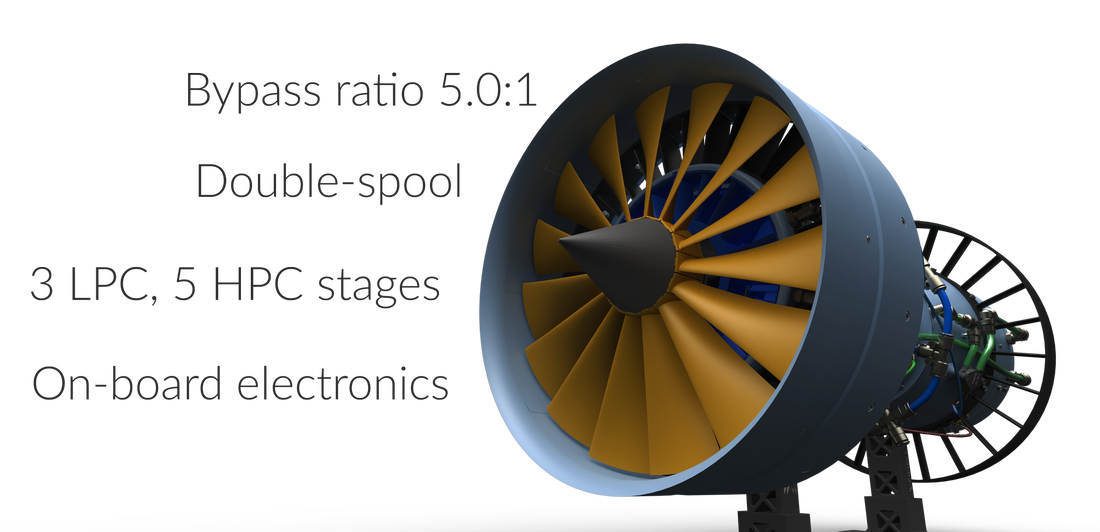

The X-Plorer 1 has successfully completed the first phase of testing which included a series of static runs! This was the first time the engine was actuated by air alone with the structural integrity of the 3D-printed assembly also put to the test. The on-board electronics were also tested for performance in the range exhibited by the XP1.

Reaching this milestone means that we not only have a working model to the capacity that we expected but also that it has cleared checks for wind tunnel testing which will be scheduled for autumn 2017. JetX president Chris Triantafyllou said: Today marks a major milestone for this project which has been in the making for the past two and a half years! We have now acquired data or identified areas to be improved that would not otherwise be possible before or without testing. The fact that the engine remains in full working condition means that we plan to perform wind tunnel testing as well as operate it for longer and at higher speeds. We would also like to thank our trusted partner Cole-Parmer for their continuing support and extremely fast response for the evolving needs for instrumentation during testing! As the development of the X-Plorer 2 will be at full speed during the upcoming academic year, we would also like to thank each and every partner of ours during the design and manufacture of the X-Plorer 1! Check them out here.

Last week, the team met with engineering executives at Rolls-Royce to present progress of the X-Plorer 1 project and discuss key matters that will broaden our cooperation on a technical basis. Rolls-Royce joined JetX as a key sponsor and we are delighted to be working with one of the greatest jet engine manufacturers with influence on the aerospace sector worldwide. JetX plans to join the RR efforts, particularly of the Inchinnan team to promote STEM subjects and encourage young people to pursue engineering by presenting the wide range of interesting areas and projects. Furthermore, Rolls-Royce has kindly offered to assist us on a knowledge and technical basis where possible to help us further raise the level and quality of future projects. In a statement to the University of Glasgow's media team, Garry Train, the Rolls-Royce Manufacturing Executive for Compressors, said:

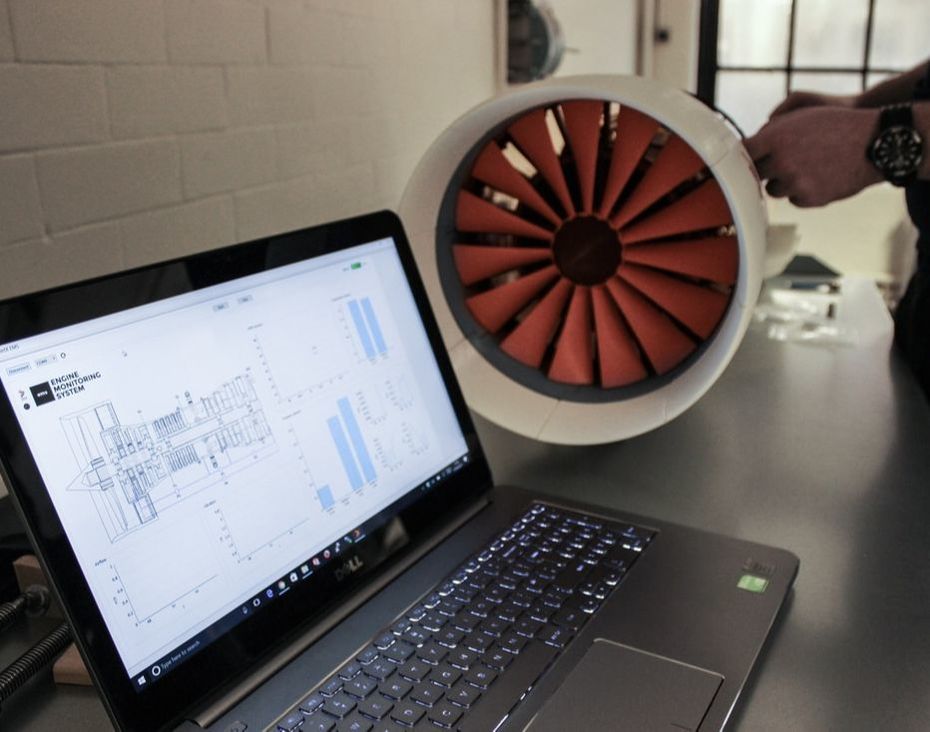

February and March were incredibly busy months that saw the final parts being 3D-printed, including a number of revisions. Some late issues with on-board electronics have been fully resolved, whilst the software that supplements the EMS and allows us to monitor engine performance in real time, wirelessly was also finalised. The electronics and pneumatics are now being fitted while 88 threaded inserts are heat-pressed in nacelle parts to allow for practical assembly and disassembly.

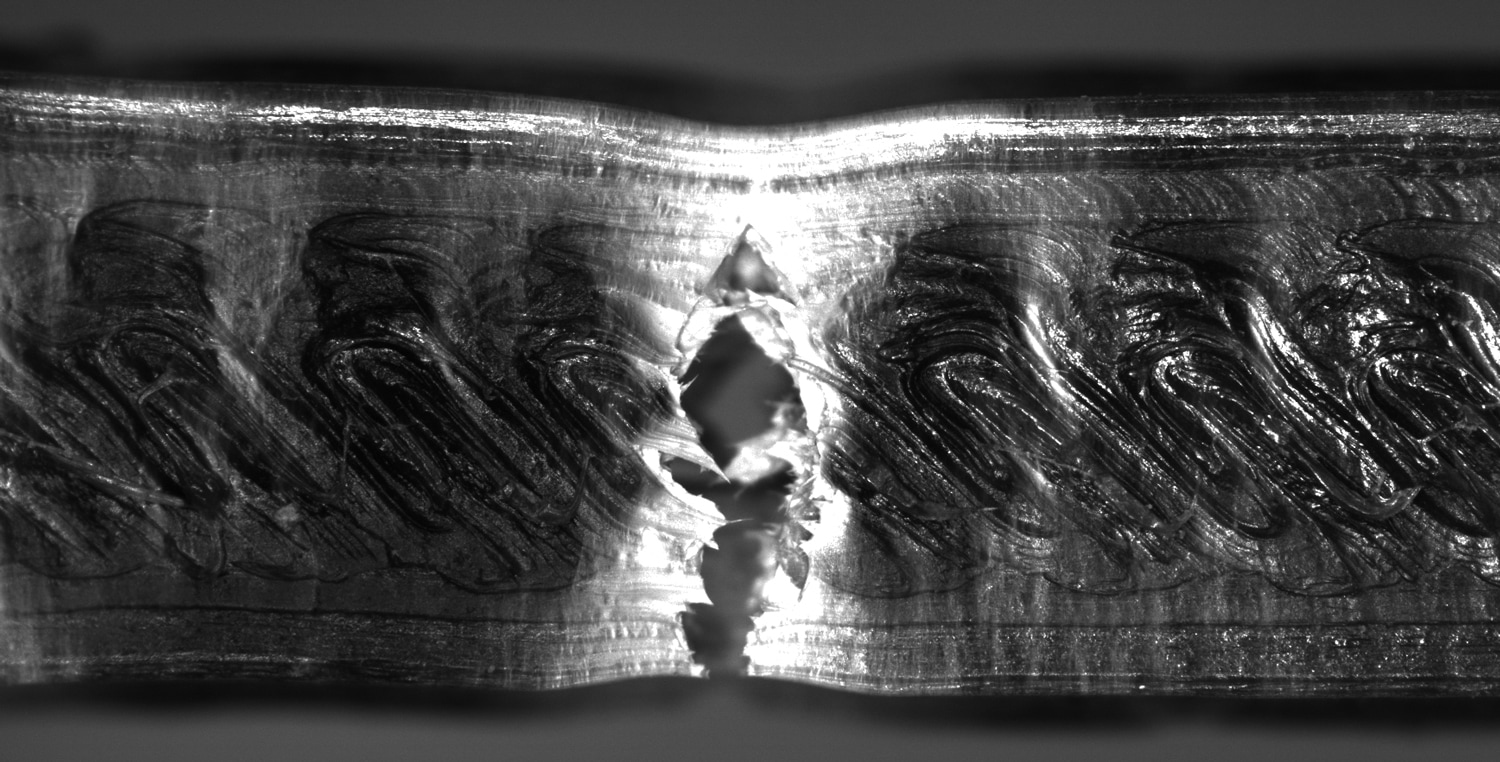

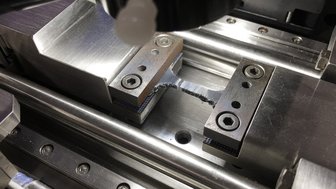

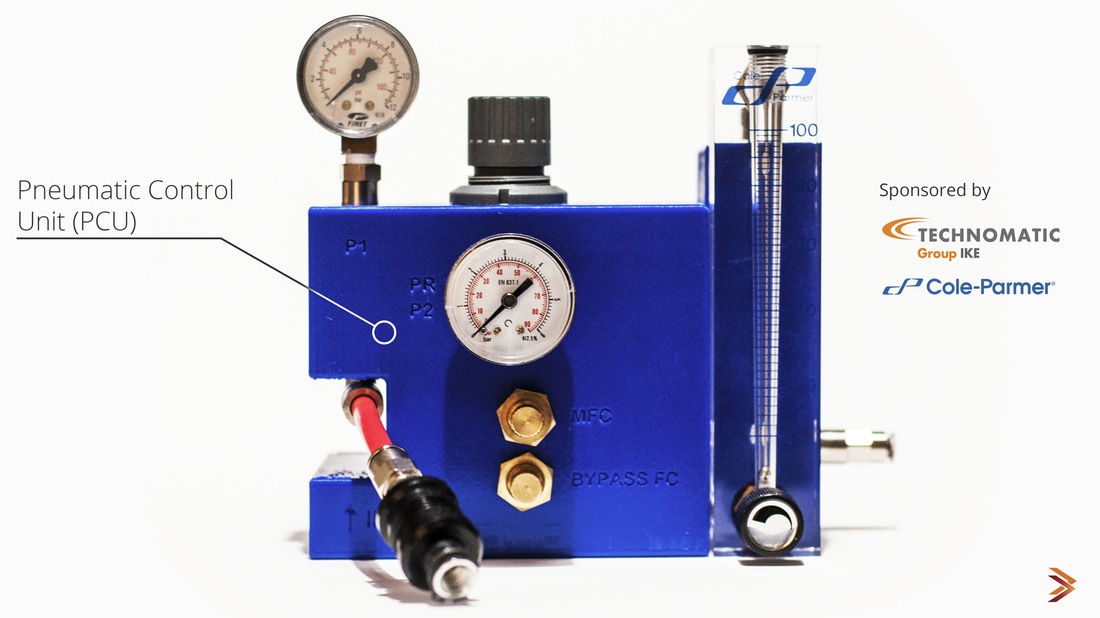

The production is expected to come to an official end next week with pre-testing scheduled for late May. You can also read the story by the University of Glasgow's Media team here! Last week saw testing across three areas taking place to either test components before these are fitted onto the X-Plorer 1 or to enhance our understanding of the mechanical behaviour of 3D printed parts. The week kicked off with electronics checks to test the performance of sensors in environments more realistic to the anticipated in-service ones, check the wireless communication links and readiness of the Graphical User Interface (GUI). 5 sensors have already passed the checks, 1 is pending and issues identified with 4 of them are being addressed this week. The GUI was also found to respond and function well, with only a few bugs left to be sorted by our software engineers. Finally, we conducted a series of preliminary mechanical tests on 3D printed specimen, manufactured in different orientations. The purpose of these experiments was to quantify the relation and degree of dependency of the 3D printing structure on the mechanical (tensile) capacity of the part. Apart from enabling us to observe the difference in failure modes, the tests have given us data that will be used to optimise and build more complex and accurate FEA models that are based on composite structures. The long-term objective is computationally model 3D printed parts more accurately, which is particularly challenging due to a number of factors. Testing will continue this week, as assembly progresses. A failure of an LP shaft segment led to intensive work by several of our design engineers who have come up with an improved design. Even though re-printing the parts meant that just over 115 hours were added to the printing schedule, the new design is thought to offer multiple benefits and its immediate implementation will be completed by next week. The PCU was assembled in late December and consists of 32 components housed in a 3D-printed, custom-made casing. In fact, the main part of the casing was printed in one go, surpassing the compressor casing to become the longest single print, taking 58 hours and 30 minutes! The whole casing used up 125 metres of Formfutura's Easyfil PLA. The PCU is designed to handle a range of compressed air sources and regulate it to the desired flow rate and pressure before it is injected in the X-Plorer 1 propulsion chamber via the on-board pneumatic assembly. The 21 high quality Camozzi rapid fittings are housed in the PCU, which alongside the 24 additional fittings mounted on the X-Plorer for operational and monitoring purposes were kindly sponsored by the Technomatic Group IKE. In normal operation, the PCU can supply up to 100 litres of air per minute, monitored and adjusted using an impressive acrylic flow meter, courtesy of Cole-Parmer, leading manufacturer of scientific equipment. Across the project, the manufacture of all core components is now complete! Assembly continues, as the first stators were mounted last week and the assembly of the drivetrain is expected to start next week.

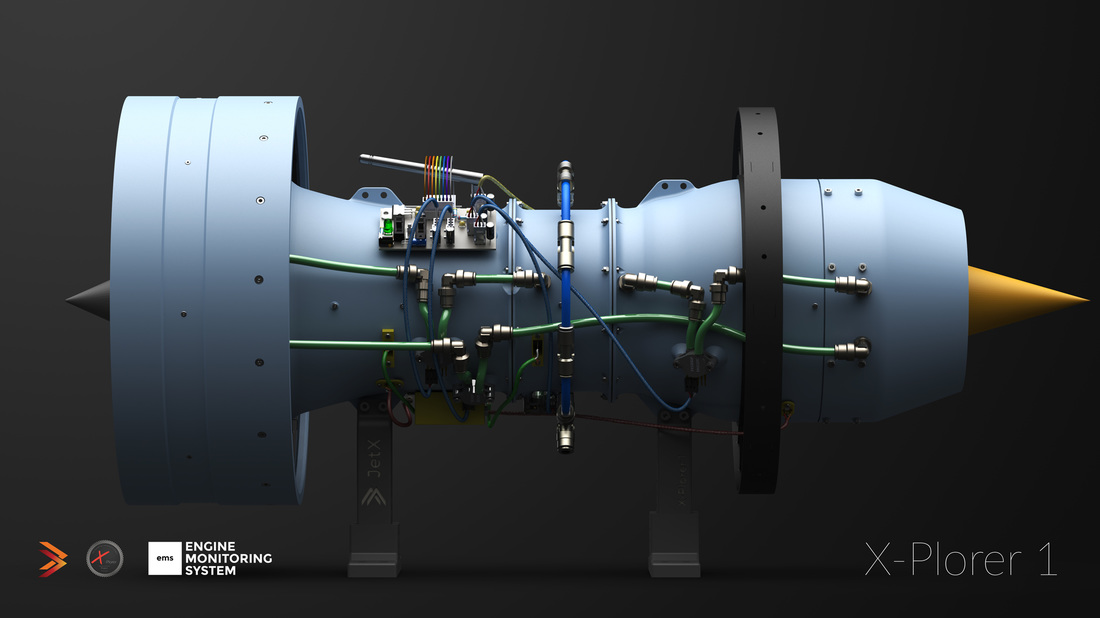

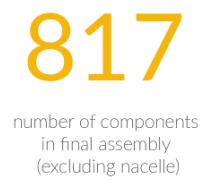

The team will meet later this week for a briefing and to assess progress for the X-Plorer 2. Find out more about the services and products of Technomatic and Cole-Parmer following the links: We proudly present the complete design of the X-Plorer 1! After two years of hard work of 46 engineering students, JetX's first turbofan engine design has now been finalised. Reaching this stage is of great importance for the organisation, as the process has been challenging on many different levels. Designing a sub-scale engine that obeys the theoretical models developed as closely as possible has taken considerable resources and adjusting all parameter for printability has offered an all-round engine development experience for everyone involved.

X-Plorer 2In the meantime, we keep pushing the boundaries and capabilities of our design. 12 new members joined the team in early October and will work with their respective teams to optimise the engine design and implement improved or more advanced features in the X-Plorer 2.

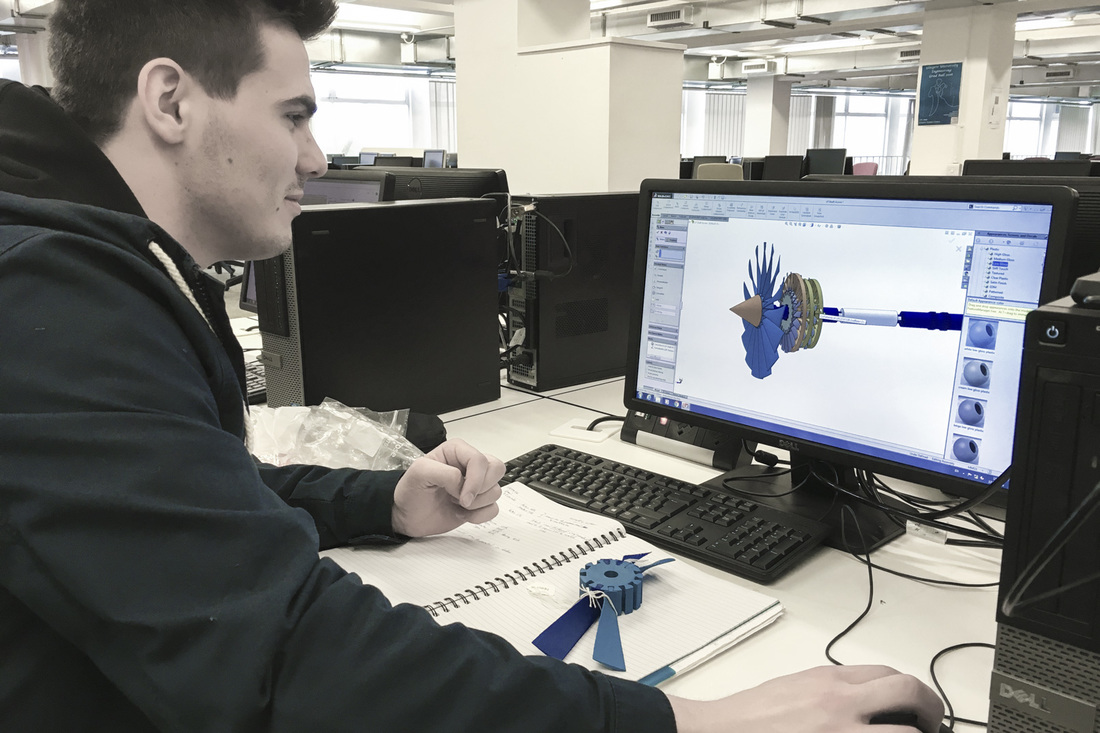

The second engine of the X-Plorer family will be optimised in terms of ease of assembly and reliability in the next couple of months and then further improved in terms of performance, based on testing results from the X-Plorer 1. Let us know what you think of our design and make sure you stay tuned for production updates as well as more content from the current engine! From shaft connectors to casing sections and from nozzle guide vanes to fan blades, the list of the first 100 parts to be prototyped has had it all! All parts up to this point have been prototypes and test that will not be part of the final engine model. Team members from the Compressor, Turbine, Power Transmission and Exhaust teams have been designing these parts and 3D printing has been fully utilised to help our engineers optimise their designs, as well as interact with these. Needless to say, many of those were tested to their limits in the name of engineering and have ended up broken, only to be replaced by improved versions. With an average print time of 3 hours and 5 minutes, our Overlord has consumed over half a kilometre of plastic in the process! The record for the longest print so far is held by a section of the inner casing which took just over 48 hours to print. It is not long until we begin manufacture of the final components and we are all looking forward to that! Don't forget that you can always check the latest 3D printing numbers here.

Following the end of the spring exams, all teams resumed work on the project. At a team leaders' meeting that took place last week, we checked progress across all teams and the heads highlighted the pending tasks.

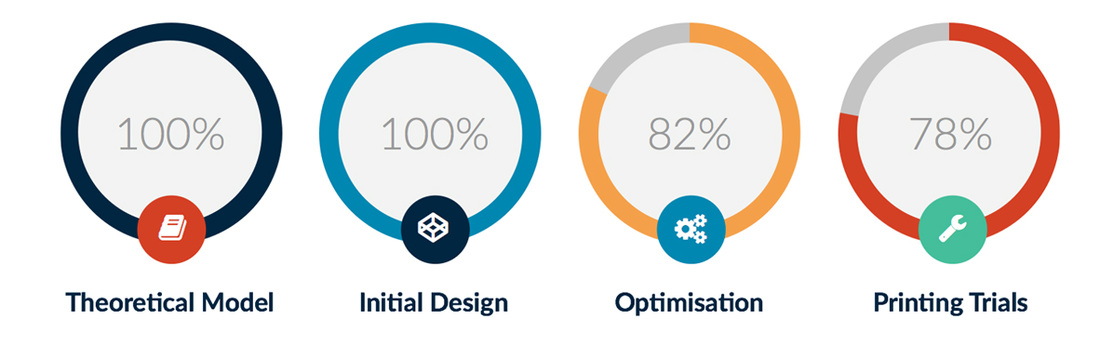

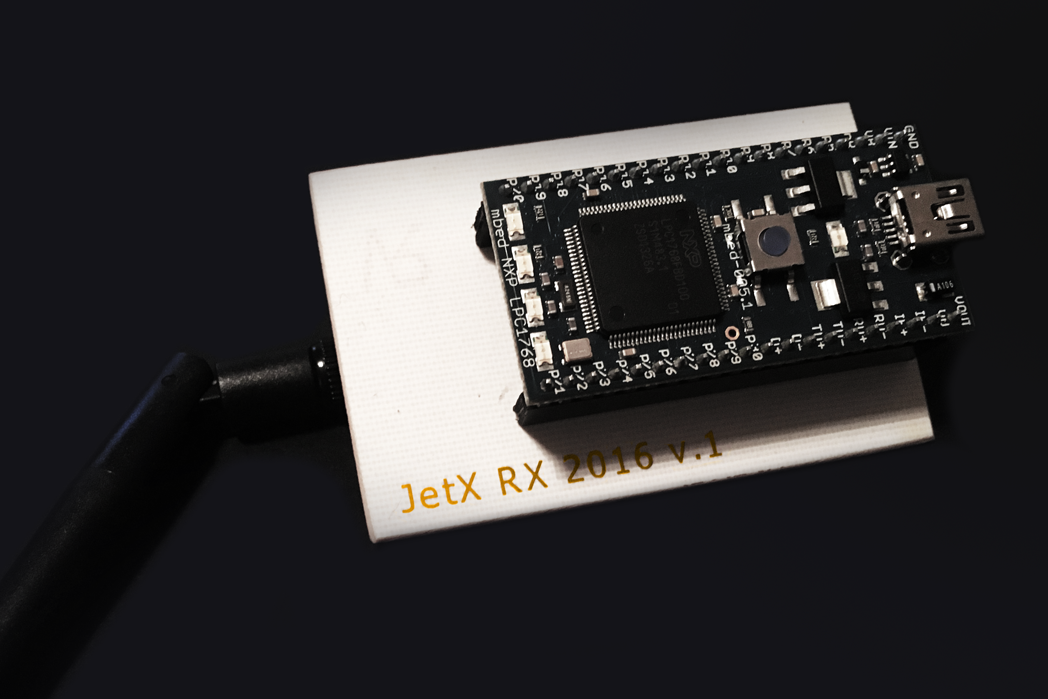

The findings from printing trials that took place in the last couple of weeks were discussed to make sure a common strategy is followed for subsequent design changes. This week also marks the crossing of the 200-hour mark for 3D prints. Having already prototyped 94 parts, the trials continue and it's not too long until the final parts enter the printing queue. With the Printed Circuit Boards (PCBs) ready and assembled, the graphical user interface is being finalised. The Engine Monitoring System (EMS) is coming together ahead of schedule and our Electronics team has calibrated and tested all sensors. The EMS consists of 10 sensors that will be continuously monitoring and logging vital performance data of the model while testing, including air pressure & speed, shaft speed and temperature. To enable wind tunnel and remote testing, the X-Plorer will be able to transmit the real-time data wirelessly. It comes with a built-in APU to eliminate the need for a wired power supply and two 100MHz ARM micro-controllers are employed to process the data. Design 90% complete

Members and leaders across five teams came together last week to assess progress up to the end of 2015 and get updates for the strategic planning leading to the completion of the X-Plorer.

Following the board's news, each team gave a presentation to the club, enabling everyone to get an in-depth look into other teams' work and current standing. The presentations were part of our continuous work towards bringing people from different backgrounds together and showing the bigger picture of what we are working on. The meeting followed the publication of interim satisfaction levels, where 94% of the members said that they are very glad to be part of JetX and 88% have found the project to be a good chance to develop their personal and professional skills. We are also very happy to welcome two new sponsors, the Dutch Formfutura and Plastic2Print who are supplying us with 3D printing supplies. TeamA record breaking recruitment season for us has come to an end, after receiving six times more applications than vacancies. A rather competitive year for all teams and responding to public demand we increased the team's capacity to a maximum. Well done to all 30 engineering students coming from 1st year to postgraduate level who made it to the team. We are glad to welcome many enthusiastic people and a particular welcome to our newly created Electronics Team. ProjectA revised timeframe has been published and most teams have to move quickly to finalise their theoretical models, as well as reach December's target to complete the first design. The long and insightful processes that include analyses (FEA & CFD) have began and the first official printing trials will start in the next two weeks. CommunityWe have many exciting things in the making and we will soon be announcing two new sponsors, further expanding our cooperation with external parties.

The highly anticipated CFD training session is now being finalised and places will also become available for non-members closer to the date. For all upcoming events make sure you keep up to date with our page on Facebook or Twitter and for any enquiries drop us an email. |

JetX Engineering NewsFor all latest updates on the club, the team & the project. Archives

November 2020

Categories

All

|

The Project |

The People |

|

© COPYRIGHT 2014-2021. JetX Engineering ®

RSS Feed

RSS Feed