|

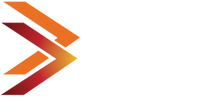

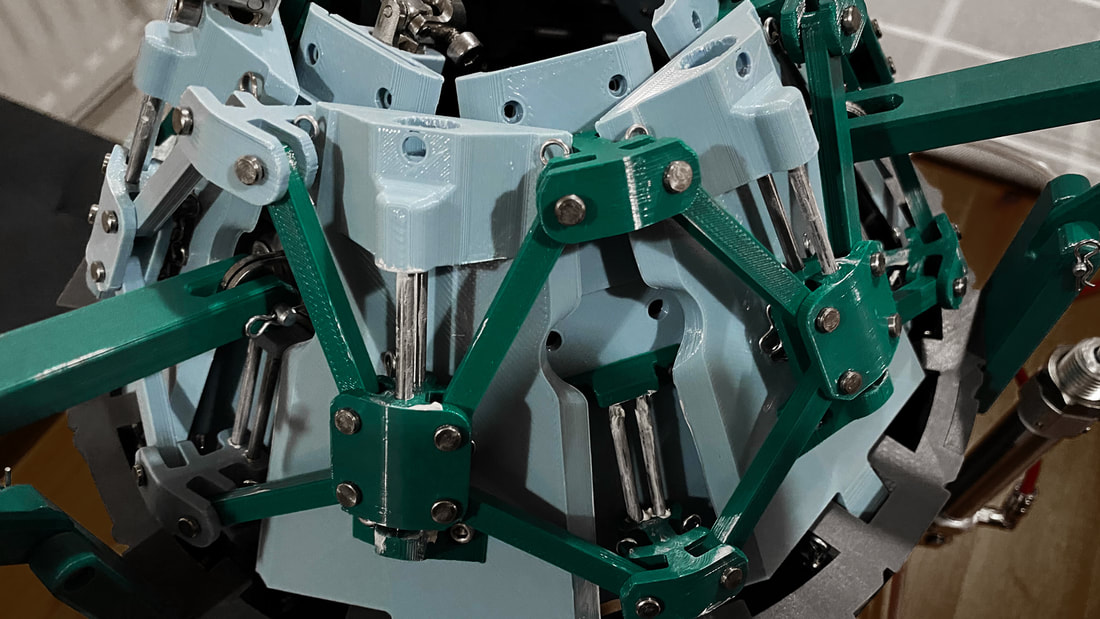

It goes without saying that 2020 hasn't turned out as planned for pretty much everyone, ourselves included. With the pandemic still affecting a big part of our everyday lives, consecutive project delays and a nearly-spent budget, it has been difficult to keep the momentum going over the last few months. However, here's how we managed to get a great deal of work done to piece together our most complicated project. Kronos vs X-Plorer 2 Since the beginning of the previous academic year, we were conscious of Kronos falling behind schedule and decided to focus our efforts on it, meaning that little manpower was left for X-Plorer 2. Given that Kronos has taken the centre stage since 2018-2019, this wasn't a big disruption to our work schedule, but it did mean that X-Plorer 2 was eventually suspended and unfortunately we have no plans to continue it anytime soon. We tried our best to remain equally committed to both programmes since 2017 for different reasons; X-Plorer 2 being a natural evolution of the 1 and EC predecessors would allow us to fine tune things that have been flagged up during the assembly and use of both. It was about making better use of the information gathered in the process, whereas Kronos came with a whole new set of features and subsystems that we were very excited to bring to life. After all, Kronos was the much bigger challenge for us and we couldn't not continue the tremendous amount of work that has gone into it over the last three years. Where are we now? By the start of February, aerofoils work was almost complete but we were faced with difficulties around the exhaust and the vectoring assembly. For the Kronos core, the integration work began in March, bringing together the work of different teams in our largest assembly structure to date, which currently includes 114 unique subassembly configurations and a total number of 3081 components! During lockdown we managed to complete a large percentage of essential test prints, but were faced with a hardware failure of our resin printer which pushed us back for another couple of months. As of November, we've clocked in over 300 hours for FDM test prints and 200 hours for DLP prints, which include over 100 fir tree tests for different stages and a near full-complexity prototype of the variable exhaust. We have also completed crucial electronics testing, from validating new airspeed sensors, electropneumatics control, visual feedback/LEDs and heat control. Coming up We are currently testing some final mechanical aspects of the exhaust and once this has been approved the final printing will begin! This might happen before the end of the year, but it is now evident that project completion is scheduled for mid 2021 assuming no major obstructions get in the way again.

Over the past three years, we have devoted a huge amount of time and resources towards Kronos, which further intensified in the last year. There were a lot of things that didn't go exactly to plan but our goal is now within reach and we can't wait to put all the pieces together! We can confirm that Kronos is our final project but we would like to thank all of you that have supported us over the years to any capacity. We will have some exciting updates over the next few months, so keep an eye out for them! After more than two years in development, Aeolus is launched to deliver a modern and concise learning resource for jet engines! What is Aeolus?Aeolus is an educational platform that is aimed at younger engineers (or aspiring engineers) that want to learn more about jet engines or propulsion in general. It currently consists of 9 chapters that cover most basic areas of interest from component design, working cycle analysis and operation characteristics. It has been a background project for us, as both the inclusion of information with the right degree of complexity and the production of over 65 new graphs, schematics and illustrations were both fairly time intensive. From the platform's homepage, you can navigate to all chapters or jump straight into a subsection using the full directory. How is it any different than other resources?Of course, we haven't redefined the principles of propulsion so you will be able to find most of the information provided in other places if you look for long enough. However, there are two reasons why we still felt that Aeolus was going to make a positive contribution among those resources:

Even though a huge amount of time and effort was put towards Aeolus, it is provided for free for everyone, as part of our educational goals. Will there be new content?Yes, we're looking into adding new and/or supplementary sections, but not in the immediate future. Having said that, if you've read or used Aeolus and have a suggestion for new content, please use the feedback form within the platform and we'll take that into account!

Also, if you would like to use any of our illustrations or graphs for your project/presentation (applies to non-commercial uses/applications), you are welcome to do so with attribution (either by writing JetX or our website URL). Again, if you have found Aeolus to be helpful in such a way, we'd love to hear from you through the feedback section at the platform. Applications are now open for 7 teams including the newly formed Propulsion team! Later this year, we will be celebrating 5 years of JetX during which we have engaged over 100 engineering students and reached out to hundreds of pupils and enthusiasts from the aerospace, 3D printing and education communities. The countdown has now begun for Kronos and X-Plorer 2 both due to be completed in 2020 and this presents a unique opportunity to existing and new member to follow those last stages of the projects. Whilst Glasgow-based students can apply to join the teams, Masters students in Sheffield can work on personal projects tied to the X-Plorer 1 EC, but applications will not be accepted online at this point. Interested applicants should reach out to ACSE for more details. New for 2019-2020This academic year also marks the start of another exciting collaboration and the establishment of our first undergraduate design team abroad. The newly formed Propulsion team at the University of New Hampshire in the US will be led by Matt Bowring and will focus on the complicated design of more efficient propulsion chamber. A performance issue with the existing chambers was identified last October and some testing in isolated assemblies as well as the X-Plorer 1 has been carried out over the past year.

Students from the University of New Hampshire may also apply online until the 13th of September. The deadline for UK applicants is the 27th of September and shortlisted candidates will be contacted a few days later. Follow the link below to access the applications page and find out more information on the teams and positions. Vacancies for some Glasgow-based teams are quite limited, so we'd advise interested applicants to apply as soon as possible! Good luck everyone! We were delighted to have been recently hosted by the Institution of Engineering and Technology (IET) to exhibit the X-Plorer 1 at the annual instalment of the Royal International Air Tattoo! Vice-presidents, Ross and Hamzah, were joined by team advisor, Alan, to speak to the public about what it is that JetX does, how the IET promotes engineering particularly among younger people and generally about all things aerospace. Given the nature of the event, there was no shortage of aviation enthusiasts and students of all ages interested in our use of additive manufacturing. The team arrived on Thursday to begin setting up the stall with our information leaflets and brochures, as well as the X-Plorer 1 and the all-new "desktop fan"; a scaled replica of the fan design that is found on the X-plorer 1 EC currently housed at the University of Sheffield. Once set up, the team took a behind-the-scenes walk about the Techno Zone before the air tattoo opened to the public on Friday. After an (extremely) early and wet start to Friday, the weekend of flight was underway. However, due to the temperamental British summer, no air displays took place. To remedy this, we were instead delighted to meet and have a chat with Tim Peake in the Techno Zone. Whilst Hamzah and Alan got their picture with him and signed one of the annual reports, Ross only managed to almost walk into him as they passed through a door. The remainder of this day was spent talking to the public and fellow exhibitors alike, with interest from both equally. On Saturday, air displays finally began. Highlights included a centenary celebration of British Airways with a Boeing 747-400 flanked by the Red Arrows and an opportunity for Ross to see a childhood favourite; an Apache attack helicopter.

With Ross having left late on Saturday, it was up to Hamzah and Alan to close out RIAT 2019. After an exhausting weekend, there was no respite to come with Sunday being the busiest day of the three. Nonetheless, they survived as we almost ran through our entire stock of 3D-printed keyrings! Be sure to check out an interview from Hamzah, recorded kindly by Colin McKenzie of the IET Aerospace Network discussing what JetX is, what we do and why we do it, available here. The team loved their time at RIAT 2019 and are keen to explore further opportunities in the future alongside the IET, promoting engineering to the younger generation and the general public. We would also like to thank Robert Allison and Robert McLaughlan of the IET for their help in making this possible, as well as all the volunteers and organisers for this great experience. You can find out more about the institution's goals and activities by following the link below. JetX will be joining the IET in the Techno Zone ® of the Royal International Air Tattoo 2019!10/7/2019

We are trilled to be joining the Institution of Engineering and Technology in Gloucestershire next week, for 3 days of STEM, aircrafts and stunts! This will be our first year exhibiting at the RIAT and we are looking forward to meeting hundreds of aerospace enthusiasts of all ages, as well as enjoying the air tattoo experience ourselves.

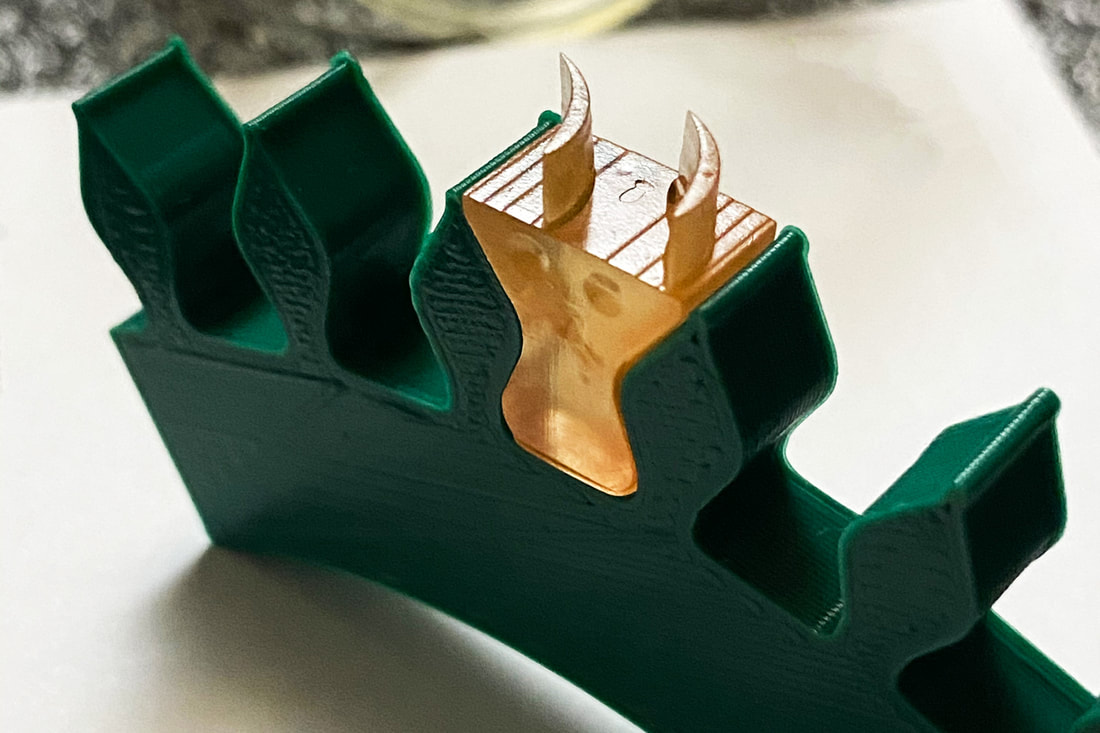

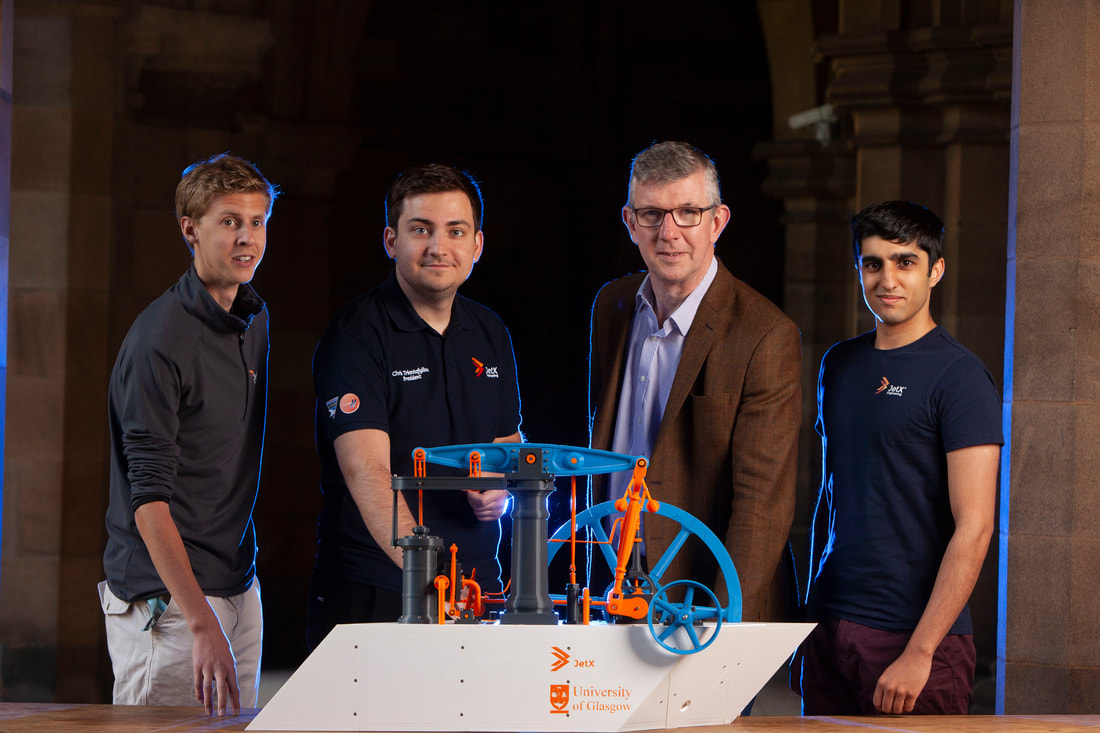

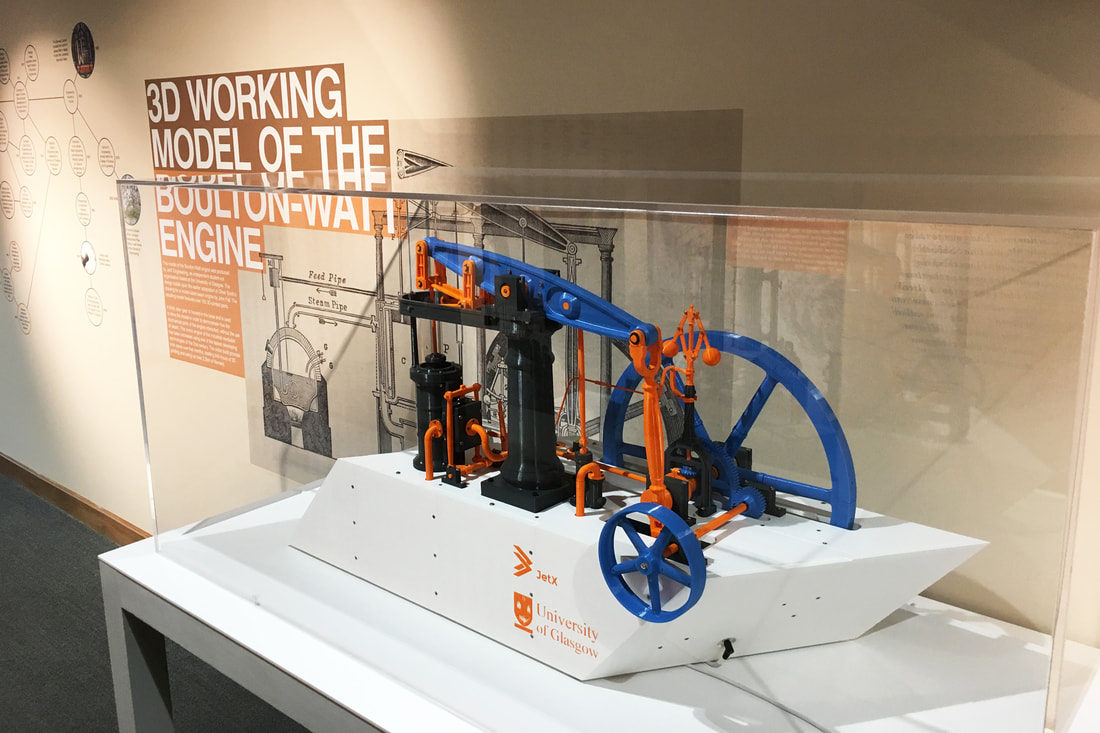

Taking place between the 19th and the 21st of July at RAF Fairford, the airshow will bring together over 30 air arms from 20 different nations. Over 30 companies and organisations will be in the Techno Zone- the aviation themed but STEM-focused zone of the airshow and we will be there along with the X-Plorer 1 and a 45cm replica of the X-Plorer 1 EC fan. Tickets can still be bought from this link. Looking forward to seeing everyone there! After 4.5 years of designing aerofoils, carrying out CFD simulations and discussing exhaust arrangements, a steam engine model might seem off-topic. To reassure the aerospace enthusiasts among us, we are not changing our course! We have to admit that it was quite fun, so we won't rule out future projects with a difference, but this was all done to celebrate a truly great engineer of our city and university. Why?2019 marks 200 years from James Watt's death and bicentenary celebrations have been in the making for a while now. Born in Greenock in 1736, James Watt was one of Scotland's most famous inventors and, undeniably, one that played vital role in the dawn of the Industrial Revolution. Watt was working as an instrument maker at the University of Glasgow when he had the opportunity to investigate the Newcomen engine. His ideas and inventions resulted in a dramatic increase of the engine's efficiency, making it much more commercially attractive. Matthew Boulton offered the financial and entrepreneurial support that Watt needed to eventually install it in mines and mills across the county and beyond. The University of Glasgow has planned multiple events to celebrate the legacy of James Watt and the idea of a working 3D-printed engine model was put on the table. We were honoured to be the first student organisation to be approached by Prof. Colin McInnes with this opportunity in December 2018, as the organisers recognised that thanks to our experience building jet engine models, we would be most capable of delivering this in time for a public exhibition which is now open. They were not wrong and we are very glad to have jumped at the opportunity! Despite being quite different from what we usually do, it was simpler and the historic aspect of the design and working principle was an attractive point for us. How?The room for original design was always going to be very limited with a project like this, but that was fine with us. We wanted to focus on the building stage, the model's actuation and the delivery of an interactive exhibit, which kept us busy enough for just over 5 months. The design builds upon the earlier adaptation of Oliver Smith’s drawing for a model-sized beam engine by John Fall. John's fantastic work was an excellent starting point for us, that was followed by scaling adjustments, certain geometrical simplifications and a lot of time spent splitting and re-assembling parts for ease of 3D printing and assembly. A new, simple but modern base was designed to house the electronics and the components that move partially beneath the baseplate. The result is the largest additively manufactured working model of this design which features over 150 3D-printed parts. Our intention was to use a linear actuator to drive the model as close to the original piston action as possible. However, upon testing that, the specific actuator we had proved unable to deliver the motion wave that was needed for smooth operation (faster stroke in the centre and better acceleration/deceleration at the minimum and maximum positions). Instead, a third spur gear is housed in the base and is used to drive the model in order to demonstrate how the mechanical parts of the engine interacted, without the use of steam. This iconic engine of the industrial revolution has been recreated using one of the fastest developing technologies of the 21st century. The entire build process spanned over 5 months, clocking in 845 hours of 3D printing and using up just over 2.2km of filament. (Left to right) Alan Hewett (Aerofoils Team Advisor), Chris Triantafyllou (President & Co-Founder), Prof. Colin McInner (James Watt Chair, Professor of Engineering Science) & Hamzah Mushtaq (VP for Engineering) Where?The model is now at its home for the next 5 months; the James Watt exhibition at the University of Glasgow Library! We would like to invite anyone who is around Glasgow and would like to see the model running to visit the exhibition which is located on the ground floor and can be accessed free of charge. The exhibition opened its doors on the 6th of June and has also been part of this year's Glasgow Science Festival events. You can read the university's news story about the project here, along with a short video. You can also find more information on James Watt events around Glasgow and the rest of the UK here. Finally, we would like to thank Colin McInnes from the School of Engineering, Ross Barker from University Media, Siobhan Convery from the University Library, Chris MacLure from the Hunterian and the rest of the Bicentenary committee for all their help. We'd also like to thank all the media outlets that wrote about this project and we hope this will encourage more people, and younger ones, in particular, to visit the exhibition and find out more! A permanent project page will soon be available on our website with more information.

Racing Into the Future - Highlighting student societies' achievements across the UK & Ireland31/5/2019

Last week, we had the pleasure of visiting Dublin to attend the first “Racing Into the Future” event, held at Dublin City University. The aim of the event was to bring together leading student societies from across the UK and Ireland to share their achievements, pushbacks and what ultimately drives them to keep pushing the boundaries of student projects. At our stand, unfortunately, without the X-Plorer 1, we really enjoyed talking to a lot of attendees and fellow members of other participating societies about our completed and existing project, as well as why a fireless engine model gives rise to multiple learning opportunities on both technical and non-technical levels. The busy schedule of this one-day event also included a number of presentations from students, academics and the Formula Student UK Head Design Judge, Neill Anderson. Our team was also represented at the student panel discussion by VP for Engineering, Hamzah Mushtaq. Hosted by James Carron, co-organiser and Team Captain of the UCD Formula Student team, Hamzah was also joined by Erik Mårtensson of the Edinburgh University Formula Student team and by Bart Baran, co-founder of Éirloop.

The hour-long panel presented a range of thought-provoking questions, aiming to explore the motivations of the individuals and what drives those in positions of responsibility to keep pushing forward. By questioning the very reason we all joined our respective organisations in the first place, and how our roles have changed massively over the years, we were able to provide a comprehensive list of benefits of being part of such societies. However, it was important to also address the inherent drawbacks of investing so much additional time and resources into such projects, and the panel handled this aspect very well. JetX was in the position to contribute a unique dimension to the discussion, being one of the few organisations not working towards a specific competition. Listening to the other members' talks was also a good chance to get an insight into the support and resources other university organisations have access to. We would like to thank the organisers for the invitation and everyone who came along. Overall, we really enjoyed our time in Dublin and we are looking forward to attending next year's event! Final full team meeting for the academic year takes place as momentum builds up for Kronos25/4/2019

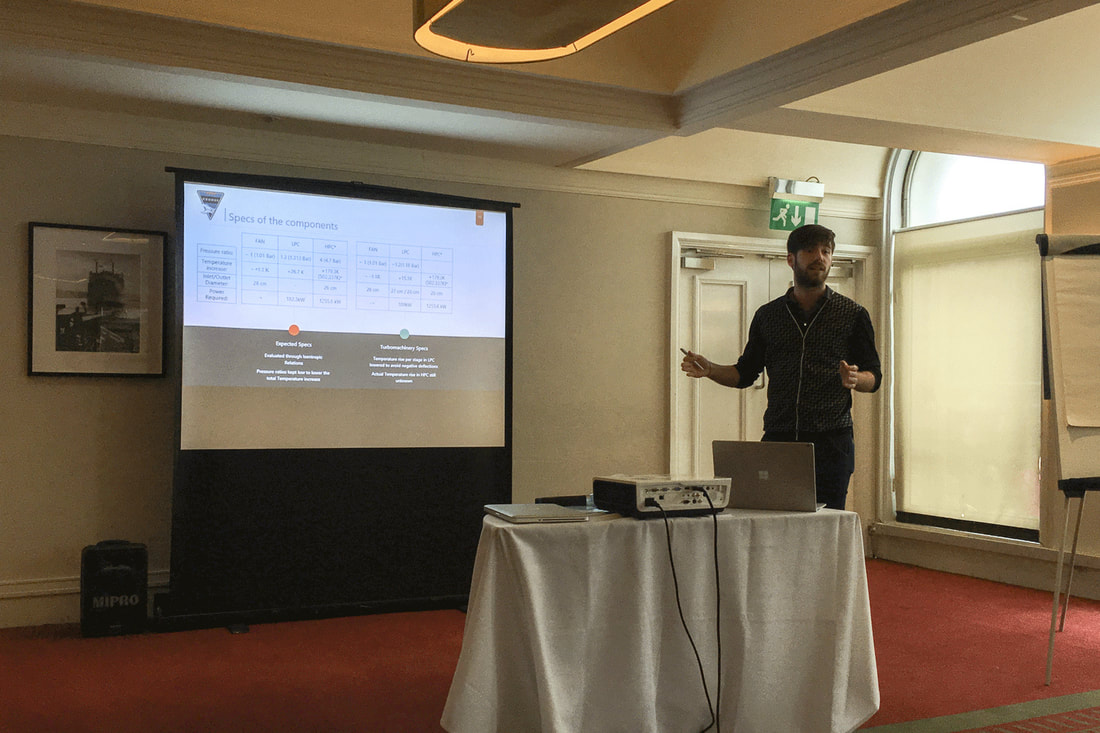

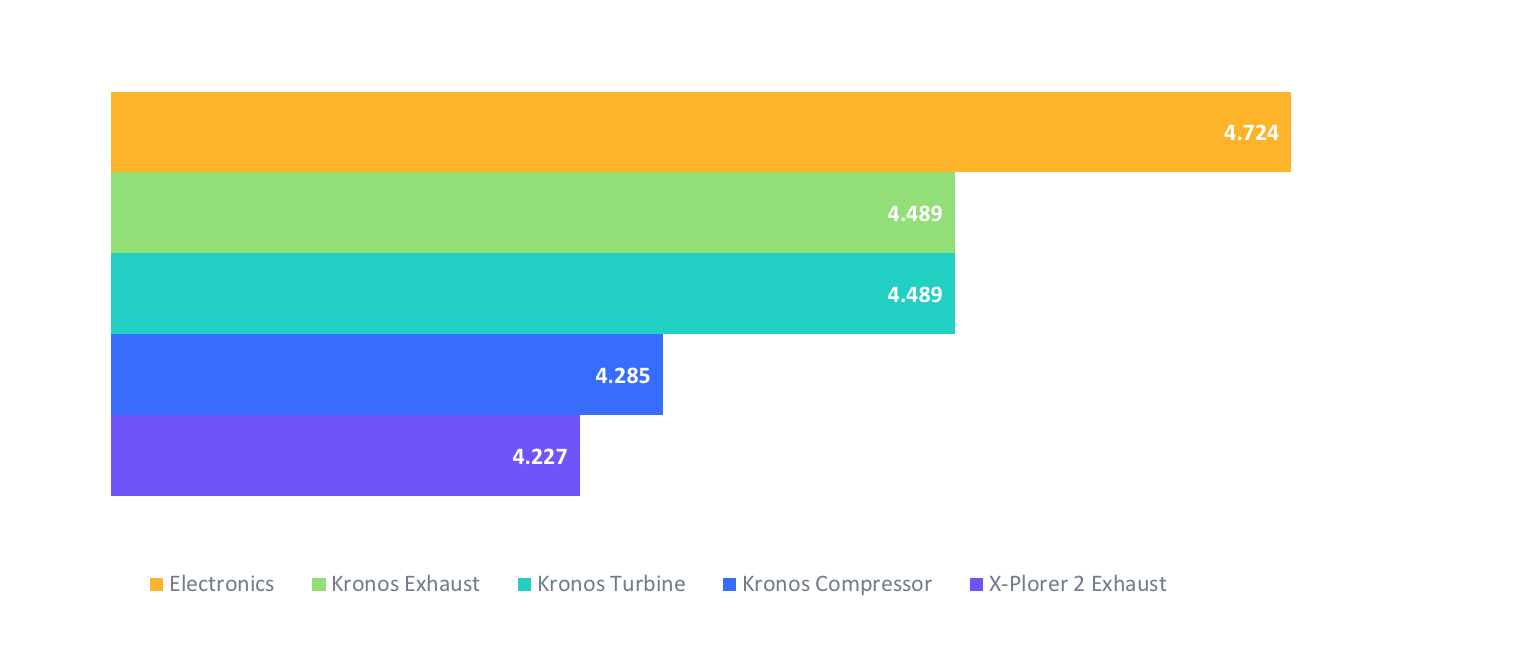

Last week, we all met for the final team presentation for this semester in a 5-hour session full of computational results, experimental findings, future plans and coffee! All teams were asked to deliver a technical presentation on all the work carried out during the academic year. Despite this being a seemingly quiet year, we had extensive discussions on the large amount of work carried out across all areas/teams. The absolute team progress has been very encouraging as far as the Kronos timeline is concerned and coincides with a strong development of computational skills which drives future design improvements. We also briefly discussed the progress of another project that has not be shared publicly so far, but it has certainly taken up several hundreds of hours for a sub-team of ours to deliver. Keep an eye our for our next news post to find out more about it! Finally, thanks to our sponsor MeetingPulse we were once again able to effortlessly collect peer assessment data during our event, where the rest of the team was asked to rate the presenters in terms of overall progress, technical content and presentations skills. Unfortunately, the Electronics team was not able to win for the second year in a row, but we'd like to congratulate the Exhaust team for scoring a total of 27.32 points out of 30 and for topping the board for each individual category too!

Last week, we had the pleasure of visiting the University of Sheffield to deliver the second ever jet engine model designed and manufactured by us, the X-Plorer 1 EC. The end of the intensive 9-month redesigning, prototyping, assembling and testing period, marks the official start of our collaboration with the Control, Monitoring & Systems Engineering University Technology Centre (UTC) within the University of Sheffield. Established in 1993, the UTC is leading research in systems and control for Rolls-Royce, supporting operations in design, development, manufacture and service provisions for integrated power systems that are used in the air, on land and at sea. The collaboration aligns perfectly with our long-term goals and objectives which, on one hand, involve continuing and growing the educational impact of our programmes for more students and through more channels (including curriculum integration) and on the other hand facilitating higher level research in areas where our engines are more attractive to use due to the lower cost and simpler operation. JetX president, Chris Triantafyllou, added: The X-Plorer 1 showed how useful it can be as an educational tool, besides being an original project that we started from scratch. Even though we were always willing to demonstrate how it can be used as an experimental platform in aerospace research, the right opportunities hadn't come up. Our collaboration with ACSE enables us to take this step in a control and systems engineering context, whilst enabling the team in Sheffield to demonstrate or test their work and devices in a whole new setting. About the ECEven though the X-Plorer 1 EC shares a lot of common features with its predecessor, it is far from identical! Although implementing all the improvements planned for the X-Plorer 2 would be desirable, this is currently still in the early design process and it would delay the start of our work with Sheffield by over a year. Our solution was to use the same core as the XP1 as the starting point and complete a number of crucial upgrades and design changes based on our experience from developing the X-Plorer 1. The full list of improvements can be found on the dedicated programme page which will be published in the next couple of weeks, but to list a few, the EC features:

3D printing of the EC started on the 10th of April and was completed 164 days later, transforming a total of 670 parts from CAD to reality for main components, development parts and spares. This added 2588 3D printing hours on our printers, on top of the 2942 hours spent on the development of the X-Plorer 1! July 2018 was our busiest month which saw 130 parts produced. Testing & Upcoming WorkDuring our visit to the Kroto Research Institute, we also had the chance to run both engines, setting two small performance records! The major objective of the change in the relative number of stators in the turbine was to improve the LP performance, which showed to be lacking compared to HP in the 2017 tests. At 200 LPM, the EC spun at 197 RPM, nearly 1.8 times faster that the X-Plorer 1.

Just before our departure, we also ran the X-Plorer 1 up to the limits of the provided air supply, with the HP shaft reaching speeds of up to 1657 RPM; over 200 RPM higher than before. Back in Glasgow, we are currently getting ready to brief the team, including the new recruits, and resume work for the X-Plorer 2 and Kronos. We already have a couple of specific areas to focus our attention on, which include tasks of relevance to the EC. In Sheffield, the team will spend the next couple of weeks familiarising themselves with the engine before conducting the first set of tests on fault diagnostics around the fan! In the meantime, MSc students within ACSE can find out more information internally on how to work on a project related to the X-Plorer 1 EC. We have a lot of exciting work ahead for all teams and we are looking forward to strengthening our ties with the University of Sheffield through a strategic expansion of our working areas to include aerospace research in the future. Applications are now open for our main intake for 2018-2019 with vacancies in 6 teams! Following a challenging year for JetX, we have returned with a very positive outlook that will keep projects running in two UK cities for the first time!

This is the first ever time that our team has been restructured and you will find detailed information about the new teams and their objectives in the relevant application pages. We felt this was necessary to serve our evolving portfolio of projects, whilst improving the student experience. This also means that teams will not be split by programme and will focus on specific skills that students have or would like to focus on. Students from Strathclyde University are also invited to apply, as we are committed to recruiting more talented students from Glasgow and this will be followed by the opportunity for MSc students to get involved with the X-Plorer 1 EC in Sheffield! Please note Strathclyde students can apply online, whereas students from Sheffield will receive further information from within the ACSE department and cannot apply online at this stage. This will be a very competitive year and we would encourage everyone who is considering getting involved to apply as soon as possible for a chance for an early interview. Good luck! Kronos Power Transmission team leader Murray Mackenzie, presented the latest updates from his team. Our third and final full team meeting for this academic year took place on Monday, amid anticipation to view the latest updated on the work across all teams! The meeting held at Hilton Glasgow Grosvenor was, in fact, the longest we have ever had, stretching over 6 hours (but we did have a lunch break)! Highlights from the X-Plorer 2 team include major progress on one of the high priority items on our agenda- the finite element modelling of 3D printed parts. The Power Transmission team has been working on recreating the geometry of an actual 3D printed part from the tool paths with the ultimate goal being to calibrate a model using ANSYS so that the significant anisotropy is taken into account. One of the two members leading the FEA research, Paul Strang, said: I think that our work on gcode-based FEA modelling is one of the most exciting areas to be working on. We have made good progress this semester and I am glad to have had the chance to get involved. Of course, we haven't reached our goal yet and will hope that we'll have a breakthrough in the next few months, as our modelling in ANSYS gets more elaborate and some testing is completed. Exhaust also presented a newer, more elaborate design for the thrust reversers that will be introduced to the X-Plorer 2, with some additional work required to address scaling issues. Progress from Kronos has been impressive, with the programme running ahead of schedule despite the initially challenging theoretical design stage. The exhaust team stood out, showing major progress on the nozzle and afterburner design and managed to run initial CFD simulations in the limited amount of time for computational simulations this semester. Exhaust team leader, Cami Leslie said: Having worked on both the X-Plorer 1 and 2, Kronos is the programme was most excited to hear about and despite the heavy workload associated with starting the design from scratch, we were incredibly motivated to deliver some of the most challenging and impressive components. I am very proud of the work we presented today and we are looking forward to seeing it to completion next year! Kronos Compressor team member Cosimo Nastasia, gave a thorough presentation on the team's theoretical model. Electronics presented what is expended to be the most major improvement for the entire EMS, both for hardware and software. The team's careful planning and appreciation for the way the systems will integrate with the upcoming engines, enabled the rest of the team to appreciate the work which most others don't usually have to get involved with. The team is expected to deliver the new system by July, when it will be used for an X-Plorer 1 variant. One of the most engaging features of our final presentations is the ability for members to vote for other teams' presentations in real time and assess them in three areas: presentation skills, technical content and overall progress. This year, this was enabled using MeetingPulse! Through their kind sponsorship, we ran live polling easier than ever before and gathered all data to present at the end of the meeting. 88% of attendees said that the use of MeetingPulse made the meeting and presentations more engaging and 7 out 10 stated that it made the process more competitive! Overall Top 5This meeting has been sponsored by

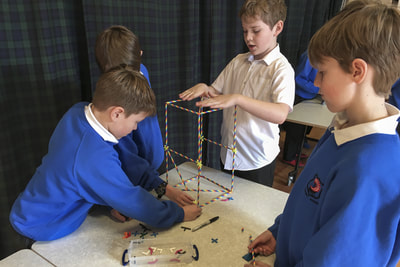

Last week, we had the opportunity to go on a two-day trip to Lossiemouth and present our work to two very different audiences; the Rolls-Royce team at RAF Lossiemouth and pupils at Hythehill Primary school! On Monday, we had the pleasure of introducing the X-Plorer 1 and our current projects at the team of the Rolls-Royce Service Delivery Centre within RAF Lossiemouth. The unit responsible for the first line of maintenance for the Typhoon engines, the EJ200, welcomed us and following a presentation on our work, showed us around the facility, giving us the opportunity to inspect an engine up close and find out more about some of the operational and maintenance aspects of the EJ200. We thoroughly enjoyed our visit to the facility and we are looking forward to returning and running the X-Plorer 1 next time! Paul Gardner (Rolls-Royce RAF Propulsion Centre) with JetX vice-president, Ross Williams. On Tuesday, we had a great time at Hythehill Primary School where we gave a talk to 4 student groups, in order to introduce students to the various engineering careers, how to get into them and what subjects are most useful. We want to not only share our experience, given that some of us didn't leave school too long ago, address some misconceptions around the engineering profession, as well as inspire the newer generation! Each talk was followed by a 20-minute activity during which the students were asked to form teams and tackle an engineering challenge. Making use of only 3D printed connectors and paper straws the groups had to build the tallest structure that can support a mass of up to 500g. Given finite resources, a limited amount of time and the ability to "buy" additional materials for a point loss, all groups were creative with many achieving the goal of this challenge! We were impressed by many of the structures and found it to be a very suspenseful activity when it came to applying the weight. It was great fun interacting with the students and we hope that they learned something knew, if they are not considering becoming an engineer already! If you are a teacher and would be interested to have us during a STEM event for your school, we would be delighted to hear from you; you can get in touch using the contact form or by simply emailing us at any time. This visit was proudly sponsored by the

JetX members from 10 teams and 2 programmes came together last week to assess progress during the first semester, individual performance and each team's plans and strategies for the current semester. The meeting, which was held at Hilton Glasgow Grosvenor, took place at the end of the most exhaustive review process so far. Feedback was collected from all levels within the organisation, from the junior team members to the board members and each team and team leader was assessed for the team function, performance, skills & personal experience. The 39-page internal report gives a good idea to all teams about any particular areas where the might have missed the target and how they compare against all other teams. Chris said: The review not only gives us an opportunity to evaluate all teams, given that the number has doubled in the last year, but also enables us to provide useful feedback or information at a time when the teams can learn from it and use it constructively for the current semester. Overall, we have been very satisfied with the progress so far and the performance of most teams. Feedback also shows that our implementation of Freedcamp earlier this year has improved cross-team communication, which has been problematic in the past. Most X-Plorer 2 teams are almost ready to deliver key performance and assembly improvements to the engine programme, whilst Kronos has made a steady start in laying the design foundations. Electronics has already delivered some interim solutions to problems of the EMS and is working towards the new system. Congratulations to the X-Plorer 2 Turbine team and Hannah Garcia Doherty for being the top scorers in the team performance and team leadership categories respectively for this semester! The full team will come together again in March for a more in-depth technical review. We would also like to thank the staff at Hilton Glasgow Grosvenor for their help and hospitality! In the meantime, a small number of vacancies has become available for both programmes and our applications are now open! Applications at this time of the year are reviewed on a rolling basis and may close as soon as vacancies are filled. You can find out more by visiting this page. Related Sponsors

October was an extremely busy month for all of us in JetX both internally and in terms of public engagements! In the first half of the month we finalised the new teams and the specifications for the new engines, X-Plorer 2 & Kronos. On the 19th we had our first full team meeting for the year, which saw a full house of the largest and most diverse team to date! All members were briefed on our targets for the year, the working procedures and introduced to our new project management platform, Freedcamp. On the 21st we took the X-Plorer 1 to the School of Engineering at the University of Glasgow for the Open Day where we had the chance to talk to many enthusiastic students and parents. We were glad to receive a lot of positive feedback which motivates us to keep inspiring the younger generation to pursue a career in STEM and engineering in particular. On the 24th JetX was also represented at the Creative Lab opening at the School of Engineering showing an overview of the project from early design to testing. We are glad to see more spaces which enable collaboration between students being introduced and hope this is also the start of increased support for student activities. On the 25th we were kindly invited by the Glasgow University Engineering Society (GUES) to their annual Dinner with Industry which took place at the Hilton Glasgow Grosvenor. We thoroughly enjoyed our evening and had the chance to talk to more engineering students and representatives from companies about the X-Plorer 1 and our plans for the future. Dinner with Industry 2017 (Left to right): Brogan Gauld, Cami Leslie, Chris Triantafyllou, Mohamed Hatab & Calum Gernon Finally, on the 27th our president along with heads of other clubs and societies from the University of Glasgow and other Scottish universities attended the IMechE's Scottish Region Annual Dinner. Chris had the opportunity to talk to representatives of other universities and get an insight of the support and resources they have access to, as well as talk to some of our partners in industry and academia from the greater Glasgow region.

We are glad to have proudly represented all our X-Plorer 1 sponsors in all these events and hope to continue our cooperation with all of them and even more in the future! So far we are pleased to see all 10 teams to have made a good start in breaking down and analysing their tasks and challenges. The theoretical design stage has now began for both programmes and the electronics team is working on replacing some parts that will improve the performance and reliability of the EMS on the X-Plorer 1 during its final testing. Our largest recruitment drive to date is now complete! JetX saw a whooping 175% increase in the total number of applications compared to the same time last year. The significant increase in vacancies due to the introduction of a second programme, Kronos, as well of a small number of non-technical roles to assist with sponsorship and event planning tasks led to an increased acceptance rate of 56%. Commenting on the increased demand JetX president, Chris Triantafyllou said: "We were expecting a steady increase in applications as we have seen in previous years, but we were very pleased to see so many applicants from all years of study expressing interest in our projects. Intensifying efforts to bring major improvements to the X-Plorer 2 and the introduction of a second programme, Kronos, show our commitment to providing a unique learning experience to more engineering students than ever before." As part of our recruitment process we also spent nearly 20 hours interviewing 51 applicants. For a second year in a row, Schedulista has been the platform of choice for organising all appointments, which ensured this was a streamlined process, making it as simple as possible for us and all applicants! In terms of top level management, Andrew Paul has been appointed Programme Director for the X-Plorer 2 and Hamzah Mushtaq has been promoted to Programme Director for Kronos. Among the 43 new recruits, 6 are students in their first year and 3 are post-graduate students with the rest coming from all years of study in-between and from 11 degree programmes making this the most diverse team to date. Commenting on the recruitment process Hamzah noted: "I'm very impressed with the overall calibre of individuals we have working on Kronos and this takes us a step closer to accomplishing something truly special. Kronos will be the only project of its kind anywhere in the world, and these people get to be an integral part of it. I feel honoured to be leading the project and I am looking forward to working with people from all engineering backgrounds in order to deliver such a complex system." All candidates have now been contacted and we have a busy schedule in terms of meetings coming up. The joint team leaders-programme coordinators briefing will take place next week and the first full team meeting with take place on the 19th of October. We are looking forward to a very exciting year ahead and working with so many bright young engineers and our industrial partners! Trouble-free scheduling by

|

JetX Engineering NewsFor all latest updates on the club, the team & the project. Archives

November 2020

Categories

All

|

The Project |

The People |

|

© COPYRIGHT 2014-2021. JetX Engineering ®

RSS Feed

RSS Feed